Rimac Technology Unveils Next-Generation Powertrain and Battery Solutions

picture: Rimac

Rimac Technology has announced significant upgrades to its powertrain and battery technology portfolio – not limited to future EV concepts but geared toward real-world, production-ready applications. The new solutions promise enhanced performance, energy density, safety, and system integration for both hybrid and fully electric platforms.

🔋 Key Innovations from Rimac

1. Solid-State Battery Advancements & Next-Gen Packaging

- In collaboration with ProLogium and Mitsubishi Chemical Group, Rimac is advancing solid-state battery development, integrating cutting-edge cells into lightweight, high-safety housing systems. These designs significantly improve energy density and thermal stability, while reducing overall system mass.

- The company’s new Evo Technology Platform leverages next-generation NMC (46XX Gen2) cells, encapsulated in thermoplastic composite housings (developed with Kautex Textron), paired with optimized thermal management systems for high-performance EV applications.

2. Scalable Hybrid Battery Architectures

- Rimac introduces hybrid-capable battery packs based on both 46XX and 2170 cylindrical cell formats, supporting cell-to-pack construction and modular scalability.

- This approach enables interchangeable cell configurations, enhanced thermal and electrical safety, and adaptability across mild hybrid to high-voltage plug-in hybrid architectures – making it ideal for applications in transition toward full electrification.

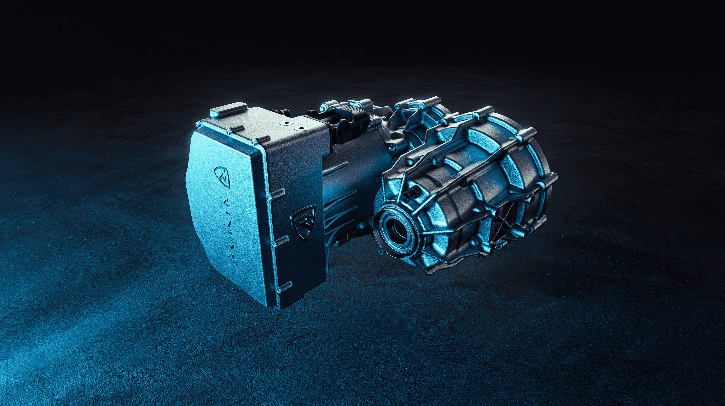

3. High-Power, Compact e-Axles and Electric Drive Units

- The new SINTEG 300 and 550 single-motor e-axles achieve power densities >8 kW/kg and torque densities >90 Nm/kg, using ultra-lightweight rotors operating at up to 25,000 rpm and featuring advanced magnet geometries.

- Configurable powertrain platforms now span 150–360 kW and 2,500–6,250 Nm of torque, covering performance sedans, SUVs, and sport-oriented vehicles.

- Notably, the Dual EM EDU 550 platform will include a High Torque XXL Axle variant — validated at >11,000 Nm axle torque and >95% peak system efficiency, targeting global OEM series production in 2026.

4. Advanced Electronics & Controls Integration

- Rimac is scaling up its ECU portfolio, incorporating domain and zonal controllers powered by NXP’s S32E2 processors.

- These next-gen ECUs consolidate legacy modules into centralized, software-definable control units capable of managing torque vectoring, battery systems, power distribution, and OTA (over-the-air) updates – supporting evolving SDV (software-defined vehicle) architectures.

⚙️ Strategic Relevance for Hybrid & Electrified Powertrains

Rimac’s new offerings align with key industry trends, particularly relevant for OEMs, suppliers, and fleet operators navigating the shift to electrification:

- Modular, Scalable Platforms: Hybrid systems based on flexible architectures (cell-to-pack, interchangeable cell formats) simplify adaptation across vehicle segments and regional regulations.

- Solid-State Battery Safety & Efficiency: Improved thermal performance, energy density, and packaging safety offer a significant advantage in hybrid applications where combustion fallback systems remain.

- High-Density e-Axles: Superior power and torque per unit mass enable downsizing without sacrificing performance – critical for hybrid and EV integration without weight penalties.

- Centralized Controls: Zonal ECUs and SDV-ready architectures enhance system intelligence, diagnostics, and update pathways – improving lifecycle maintainability.

🔍 Bottom Line

Rimac is not just innovating for the EVs of tomorrow – it is delivering tangible, production-ready components that enable today’s transition to electrified mobility. From solid-state breakthroughs to hybrid-ready platforms and ultra-compact e-axles, Rimac’s developments provide critical building blocks for OEMs, suppliers, and mobility providers aiming to meet aggressive decarbonization targets while maximizing system performance and flexibility.